Share this post

10 Different Types Of Electrical Wires & How To Choose One

- ,

- , Wiring

What Is Electrical Wiring?

At its core, electrical wiring is the network of wires and cables that distribute electricity from the power source to various outlets, appliances, and fixtures throughout a building or structure. This intricate system ensures electricity is available where and when needed, powering everything from lights and appliances to computers and entertainment systems.

Electrical wiring is more than just connecting A to B; it’s about designing and installing a system that is safe, efficient, and compliant with local building codes and standards. The choice of wire, gauge, insulation type, and route all play pivotal roles in the system’s overall performance and safety. Electrical wiring is a critical component of modern infrastructure, requiring careful planning, installation, and maintenance.

For many, the complexity of electrical wiring can seem daunting.

Safety concerns, the correctness of installation, and compliance with regulations are common pain points. However, with a solid understanding of fundamental principles and terminology, even those new to the subject can navigate these challenges more confidently. Whether undertaking a DIY project or working alongside professionals, knowledge is your most powerful tool in ensuring your electrical system’s safety, reliability, and efficiency.

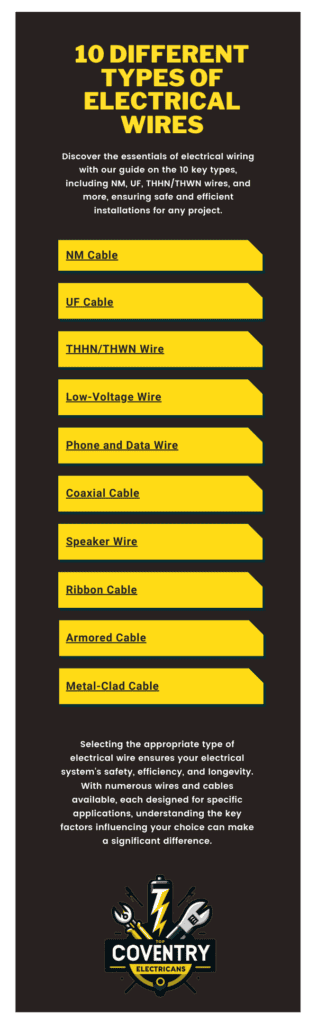

What Are The Different Types Of Electrical Wires & Cables?

NM Cable

One of the most common materials encountered when embarking on residential electrical projects is Non-Metallic (NM) cable, often referred to by its popular brand name, “Romex.” NM cable is prized for its ease of installation and cost-effectiveness, making it a go-to choice for wiring homes. This cable comprises one or more insulated conductors enclosed in a non-metallic sheath, offering protection and flexibility.

Tip: For DIYers and professionals to understand when and where to use NM cable. It’s ideal for dry, indoor environments, such as running through wall cavities, attics, and basements where it’s not exposed to moisture or mechanical damage. However, it’s not suitable for outdoor use or wet locations, like bathrooms or kitchens, without proper protection.

Warning: Always ensure the NM cable is secured correctly and not subjected to strain or damage. Its non-metallic sheath, while durable, is not impervious to punctures or tears. Furthermore, adhering to local building codes and regulations when installing NM cable cannot be overstated. Improper use or installation can lead to electrical fires or failures.

UF Cable

Underground Feeder (UF) cable is the robust cousin of NM cable, designed to withstand the rigours of outdoor and underground environments. Similar in structure to NM cable, UF cable has a thicker, more durable sheath that protects its conductors from moisture, soil, and other elements. This makes it an excellent choice for powering outdoor fixtures like garden lights, garages, and other outbuildings.

Warning: The UF cable must be installed carefully to avoid damage despite its durability. It should be buried at a sufficient depth to protect it from physical damage and must be enclosed in conduit if it’s exposed above ground or in areas where it might suffer mechanical injury. As with NM cable, adhering to building codes and standards for UF cable installation is paramount to ensure safety and functionality.

THHN/THWN Wire

THHN (Thermoplastic High Heat-resistant Nylon-coated) and THWN (Thermoplastic Heat and Water-resistant Nylon-coated) wires are two of the most versatile types of electrical wire used in construction today. They are designed for various applications, from residential to commercial and industrial settings. These wires are mainly known for their durability and resistance to environmental conditions.

THHN is ideal for dry locations and can withstand temperatures up to 90°C. It’s commonly used in the internal wiring of appliances, in conduit and cable trays for services, feeders, and branch circuits in commercial or industrial applications.

THWN, on the other hand, is suitable for both wet and dry locations, making it incredibly versatile. It shares the same temperature resistance as THHN but also includes:

- Protection against moisture.

- Making it suitable for use in basements.

- Bathrooms.

- Outdoor applications where moisture is a concern.

Warning: While THHN/THWN wires offer flexibility and durability, they must be installed appropriately within conduits or raceways in exposed or potentially damp environments to protect against physical damage and moisture. Additionally, ensure that the wire gauge and ampacity align with your project’s specific requirements to prevent overheating and potential fire hazards.

Relevant Article: Comprehensive Guide To Two Way Switch Wiring

Low-Voltage Wire

Low-voltage wire is a broad category encompassing various types of wire and cable designed for systems operating at 50 volts or less. Typical applications include doorbells, thermostat wiring, landscape lighting, and data communication cables. The primary advantage of low-voltage wiring is its safety; the shock or fire risk is significantly lower than that of standard electrical wiring, making it ideal for DIY projects.

Low-voltage wire comes in many forms, each suited to specific applications. For instance, twisted pair cable is often used for telephone and data transmission, while coaxial cable is preferred for video signals. Selecting the correct type of low-voltage wire is crucial for ensuring the efficiency and reliability of your system.

Tip: When installing low-voltage wiring, plan your layout carefully to avoid potential interference with high-voltage lines and to ensure optimal performance. Also, consider the future expansion of your system to prevent the need for costly rewiring down the line.

Warning: Even though low-voltage systems pose less risk of shock, proper installation techniques are still essential to prevent system failure or damage. Incorrect wiring or overloading circuits can lead to poor performance and damage your devices.

Phone and Data Wire

In today’s interconnected world, phone and data wires are communication lifelines in residential and commercial settings. These wires are designed to transmit voice and data signals, ensuring we stay connected to the internet and telecommunications networks.

Phone wires have traditionally been used for landline telephone connections and are typically made of twisted pair cables to reduce electromagnetic interference and maintain a clear signal. The most common type is the Category 3 (Cat3) cable, which, while still in use, has largely been supplanted by higher-category cables for data transmission due to the increasing demand for bandwidth.

Data wires, on the other hand, cater to the needs of modern high-speed internet and network connections. Category 5e (Cat5e), Category 6 (Cat6), and Category 6a (Cat6a) cables are commonly used in network installations, offering varying degrees of bandwidth and signal integrity. These cables are designed to handle the high-speed data transmission required by today’s internet, streaming, and networking needs.

Tip: Consider your devices’ distance and bandwidth requirements when setting up your home or office network. Cat6 or Cat6a cables are preferable for longer runs and higher-speed applications, ensuring you get your network’s most reliable and efficient performance.

Warning: Proper installation of phone and data wires is critical to avoid cross-talk and interference. Keep these cables separate from power lines and use appropriate shielding when necessary. Additionally, always label your wiring for easy identification and troubleshooting in the future.

Coaxial Cable

Coaxial cable, or coax, is another essential type of wiring used in residential and commercial settings, primarily for television and internet services. It consists of a central conductor, an insulating layer, a metallic shield, and an outer insulating layer to prevent electromagnetic interference. This design allows coaxial cables to deliver high-quality video and broadband internet signals over long distances.

Coax cables come in various types, including RG6 and RG11. RG6 is the most commonly used in homes for cable TV and internet connections due to its balance of performance and flexibility. RG11 offers lower signal loss over longer distances but is thicker and less flexible, making it more suited for outdoor or main-line installations.

Tip: For the best signal quality, use the shortest possible length of coaxial cable between your service provider’s entry point and your devices. Additionally, ensure that the connections are secure and the cable is not excessively bent or compressed, which can degrade signal quality.

Warning: Be mindful of the quality of the coaxial cables and connectors you use. Inferior-quality cables or improperly installed connectors can significantly impact the performance of your TV or internet service. It’s also essential to use the correct type of coax for your specific application to ensure optimal performance and avoid unnecessary upgrades or repairs.

Speaker Wire

A speaker wire is a critical component in any audio setup, connecting amplifiers or receivers to speakers and allowing for the transmission of sound signals. Unlike data or coaxial cables, speaker wire is analogue, carrying electrical currents that directly correlate with sound waves. The quality and setup of your speaker wire can significantly impact sound quality, making it an essential consideration for audiophiles and home theatre enthusiasts alike.

Speaker wires come in various gauges (thicknesses), with lower gauge numbers indicating thicker wires. Thicker wires (12 or 14 gauge) are preferred for longer runs or higher-power applications, as they reduce signal loss and maintain better sound quality over distances. For most home applications, however, 16 gauge wire is sufficient.

Tip: Consider the distance between your speakers and the amplifier when setting up your sound system. Use appropriate gauge wire to minimise loss and maintain sound quality. Additionally, ensure your speaker wires are properly polarized, connecting the positive terminal on the speaker to the positive terminal on the amplifier and similarly for the negative terminals to prevent phase issues that can diminish sound quality.

Warning: Avoid running speaker wires too close to power cables, which can introduce interference and hum into your audio system. Proper routing and occasional use of conduit or cable management systems can help avoid these issues.

Ribbon Cable

Ribbon cable, or multi-wire planar cable, consists of multiple conducting wires running parallel to each other on the same flat plane. This cable type is typically used for internal computer peripherals, such as connecting hard drives, CD drives, and other components to the motherboard. Ribbon cables are prized for their ability to handle multiple data channels simultaneously and their ease of installation within the confined spaces of computer cases.

The critical advantage of ribbon cable is its organization and space-saving design, allowing for a clean and orderly setup inside electronic devices. However, handling these cables with care is essential, as their flat and flexible nature can make them more susceptible to damage if improperly bent or pinched.

Tip: When working with ribbon cables, ensure your device has the correct cable type, as the number of wires and spacing can vary. Additionally, take care when plugging and unplugging these cables, as the connectors can be delicate.

Warning: Pay attention to the orientation of ribbon cables when connecting them to devices. Many connectors are keyed to prevent incorrect insertion, but forcing a cable into a connector incorrectly can damage both the cable and the device.

Armoured Cable

Armoured cable, commonly known by its abbreviation BX in the United States or as steel wire armoured (SWA) cable in the United Kingdom, offers enhanced protection for the conductors within. This type of cable consists of electrical wires encased in metal armour, which provides physical protection against mechanical damage and adds a grounding layer for the electrical system.

Armoured cables are typically used where the wiring is exposed to potential physical damage, such as in commercial buildings, industrial settings, and areas where the cable might run across the surface of walls or ceilings. The metal armour shields the internal conductors from impact, cutting, and rodent damage, making it an ideal choice for harsh environments.

Tip: When installing armoured cables, use proper fittings designed for them at connection points and boxes. These fittings secure the cable and maintain grounding continuity across the electrical system.

Warning: Although durable, armoured cable should not be used in damp locations unless specifically rated for such environments. Additionally, be aware of armoured cable’s added weight and rigidity, which may affect installation decisions and methods.

Metal-Clad Cable

Metal-clad (MC) cable is similar to armoured cable, providing enhanced protection for the wires inside through a metal casing. However, MC cable uses lighter aluminium or steel armour than traditional armoured cable, making it more flexible and easier to install in certain situations. MC cable is suitable for various applications, including commercial, industrial, and even certain residential settings.

MC cable often comes with an insulated grounding conductor, making it compliant with many building codes for use in places where additional grounding or bonding is required. It’s a versatile wiring solution that balances protection, ease of installation, and compliance with electrical safety standards.

Tip: MC cable can be a convenient choice for areas where the cable might be exposed or where additional protection is necessary. Compared to traditional armoured cable, its flexibility can make installation easier in tight spaces or when routing around obstacles.

Warning: While MC cable offers flexibility, handling and installing it correctly is essential to avoid damaging the armour or the conductors inside. Ensure that your installation complies with local codes and standards, particularly regarding the use of MC cable in specific environments and applications.

Choosing a Type of Electrical Wire

Selecting the appropriate type of electrical wire ensures your electrical system’s safety, efficiency, and longevity. With numerous wires and cables available, each designed for specific applications, understanding the key factors influencing your choice can make a significant difference. Here are some critical considerations to guide you in making an informed decision:

Assess The Application:

The first step in choosing the right type of wire is understanding the specific requirements of your project. Consider whether the wiring will be exposed to moisture, chemicals, temperature extremes, or physical impact. For indoor applications, NM (Non-Metallic) cable is often sufficient. At the same time, outdoor or hazardous environments might necessitate using UF (Underground Feeder) cable, THHN/THWN wires within the conduit, or even armoured or metal-clad cables for added protection.

Consider The Electrical Load:

The wire gauge, or thickness, must match the electrical load it will carry. Using too thin wire for the load can lead to overheating and potentially cause a fire. Refer to the American Wire Gauge (AWG) system to select the correct size based on the amperage of your circuit. As a rule of thumb, higher power applications, such as major appliances or HVAC systems, require thicker wires.

Understand Local Codes and Regulations:

Local building codes and the National Electrical Code (NEC) establish specific requirements for electrical wiring to ensure safety. These codes dictate the types of wire used in various scenarios, grounding requirements, and how wires should be protected and installed. Familiarizing yourself with these regulations or consulting with a professional electrician can help prevent costly mistakes or the need for rework.

Evaluate Long-term Durability:

Consider the environmental conditions the wiring will be exposed to over its lifetime. For example, wires in areas prone to moisture or chemical exposure might need additional protection to prevent degradation. Similarly, wiring in areas accessible to rodents or susceptible to physical damage may benefit from the added protection of conduit or armoured cabling.

Plan For Future Needs:

When choosing electrical wire, thinking ahead is wise. For instance, if you’re wiring a new construction or doing a significant remodel, installing conduit can provide flexibility for future upgrades or changes to the electrical system without the need to open walls or ceilings again.

Electrical Wire vs. Electrical Cable

Understanding the difference between wire and cable is essential in properly selecting your project. A wire is a single conductor, typically made of copper or aluminium, used to carry electricity. In contrast, a cable is a group of wires sheathed together, designed for a specific application. This distinction is crucial when specifying materials for your project, as the terms are different.

Wire is used for more straightforward, often single-circuit installations where a single current path is needed. It’s commonly found in residential applications for lighting fixtures and small appliances.

Cable, on the other hand, bundles multiple wires together, which can be used for more complex installations requiring multiple circuits or a combination of power, data, and control signals. Cables are often used for power distribution, network cabling, and connecting major appliances.

Installation Considerations and Safety Precautions

Proper Installation Techniques:

The correct installation of electrical wiring and cables cannot be overstated. Incorrect installation can lead to many issues, ranging from inefficient operation to significant safety hazards, including electrical fires. Following the manufacturer’s instructions and adhering to local building codes and the National Electrical Code (NEC) is crucial. When in doubt, consulting with a licensed electrician can clarify and ensure that your electrical systems are installed safely and correctly.

Grounding and Bonding:

Grounding and bonding are essential safety measures that help prevent electric shock and fire hazards. Grounding provides a path for electrical current to dissipate safely into the earth in case of a fault, while bonding connects metallic components to create a continuous electrical path. Both are critical to the overall safety of your electrical system.

Protection From Physical Damage:

Electrical wires and cables must be protected from physical damage that can occur during installation and throughout their lifespan. This includes using conduit or armour where necessary, ensuring that wiring is not pinched, kinked, or subjected to excessive force, and avoiding exposure to harmful chemicals or extreme temperatures.

Regular Maintenance and Inspection:

To ensure ongoing safety and efficiency, electrical systems should be regularly inspected and maintained. This includes checking for and repairing any damaged insulation, loose connections, or signs of wear and tear. Regular maintenance helps prevent problems before they occur, ensuring your electrical system remains in top condition.

Common FAQs On Electrical Wiring Types

What are the 3 types of electrical wires?

Solid, stranded, and tinned copper are the three basic types of electrical wires. Solid wire consists of a single piece of metal wire, stranded wire is composed of multiple small strands twisted together, and tinned copper wire is copper wire coated with a thin layer of tin to prevent oxidation.

What are the 3 types of wiring systems?

Common wiring systems include surface, concealed conduit, and overhead wiring. Each has applications, advantages, and limitations, depending on the installation environment and specific requirements.

Which type of wiring is used in homes?

The most commonly used type of wiring in homes is NM (Non-Metallic) cable, also known as Romex. It’s used for its easy installation and suitability for dry, indoor environments.

How do I know what wire to use?

Selecting the right wire involves considering the application, electrical load, environmental conditions, and local codes. When in doubt, consult the NEC or a professional electrician.

What is the old type of electrical wiring?

One old type of electrical wiring is knob-and-tube wiring, which was common in homes from the late 1800s to the early 1940s. It’s characterised by insulated copper wires running through ceramic knobs and tubes but is no longer installed due to its inability to meet modern safety standards.